Inside the AD-box there are several safety circuits constantly monitoring whether all currents flowing are within the safety limits. When the AD-box detects an unsafe situation, then all powers inside the AD-box and all powers going to the active electrode sets will be shut-down. All 3 LED's on the front of the AD-box will turn off (the battery box should be working OK and the green LED on the battery box should be on)

If the gel bridge is present at the SCSI connectors on the AD-box, then the shutdown can happen even without any electrode set being inserted into the AD-box.

If the gel bridge is at the SCSI connectors of a P32 electrode set, then a shutdown will happen when this electrode set will be plugged into or is already plugged into the AD-box.

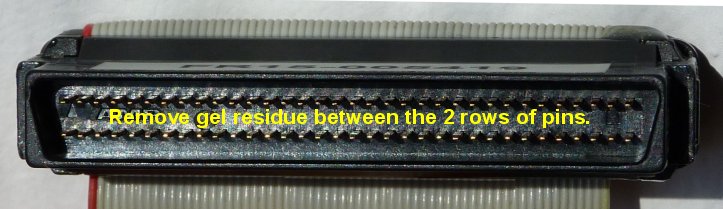

When a situation like this occurs (AD-box shuts down and all 3 LED's on the AD-box suddenly turn off) then this is because the safety circuit detected a to high leakage current going thru the guarding circuit. This is caused by gel residue inside 1 or more SCSI connectors on the AD-box or gel remains inside the SCSI connector of a P32 electrode set.

The procedure is to first visually inspect the SCSI connectors (preferable with magnifying glasses) and then try to remove the gel.

This can be done with alcohol or distilled water and a cotton cloth. Gel residue inside the SCSI connectors of the P32 electrode sets can also be removed with cotton sticks.

When a SCSI connector on the top of the AD-box is damaged or the gel can not be removes successfully, then we can replace the TOP PCB of the AD-box. The costs for replacing the TOP PCB is 350 Euro (excluding shipping costs). Replacing the TOP PCB takes 1-2 working days.

|